Best Seller

Best Seller

About Us

The SMSR series of gear boxes developed by us are heavy duty gear boxes which are supplied to renowned heavy manufacturing firms. Because, we are also exporter and supplier of the aforementioned products, we have a proper functioning supply chain management system. This ensures that there is an active and continuous supply stock for demanded products by clients. This also helps in keeping a record of our products in quarterly and monthly basis. We have knowledge and understanding of the heavy industries. Our clients demand our products for its quality and performance during peak load times. Our rugged SMSR gear boxes have helped us become a preferred choice of our clients over overseas companies. Some of the factors that distinguishes us from our industry counter parts are strong product line, large production capacity, good financial position etc.

We began our operations in the year 2005 under our mentors, Mr. Binalbhai Panchal and Mr. Maheshbhai A. Panchal. Under their leadership, we have achieved our objectives and they have also encouraged us to become a good team player.

Aim / Vision / Mission

We are guided by the vision to become a leading firm in this domain and put our best foot forward to cater to our clients diversified requirements. Our main objective is to provide quality certified products.

Our Team

We have a well functioning and experienced team of professionals which is united to work in close coordination with each other to offer high performance SMSR gear boxes. We work under the guidance of our leader Mr. Maheshbhai who is a continuous source of motivation to us. Besides, our team of marketing personnel is connected with the widespread network to offer optimum channels for our products.

Our team comprises the following members:

- Procurement staff

- Quality control managers

- Inventory and support staff

- Business managers

Clientele

We are prominent business entity for our clients in national and international markets. We take special measures to firmly establish our network in the overseas African market for our supplies. Our clients are based in different segments like Quarry Plants, Stone Crushing Plants, Asphalt Plant, Conveyor Equipments, road construction plants and more. Premium quality and timely delivery are two of the attributes which compels our clients to prefer our products.

Why Us?

We are reckoned for offering best in class quality products to our clients. With our fair and transparent business dealings, we have gained our clients trust within a short period of time.

Some of the factors that have made us the first choice in the marketplace are:

- Timely delivery of our consignment

- Customized solutions

- Quality assured products

- Modern manufacturing facility

- Experienced & professional workforce

- Upgraded production unit

- Wide distribution network

- Reasonable pricing structure

Product Range

|

SMSR Gear Boxes |

||

|

Anti Reverse SMSR Gear Box |

Stone Crusher Gearbox |

Holdback SMSR Gearbox |

|

Anti-Lock SMSR Gearbox |

Fenner type SMSR Gearbox |

Fenner Type Gearboxes |

|

Drum Mix Plant Gearbox |

SMSR Gear Box |

|

|

Shaft Mounted Gear Boxes |

||

|

Shaft Mounted Gearbox |

Shaft Mounted Speed Reducer Gearbox |

Conveyor Shaft Mounted Gearbox |

|

Reduction Gear Boxes |

||

|

Reduction Gear Boxes |

Worm Reduction Gear Boxes |

Worm Reduction Gearbox |

|

Power Transmission Gearbox |

Mining Plant Gearbox |

Hollow Shaft Gearbox |

|

Conveyor Gear Boxes |

||

|

Conveyor Gearbox |

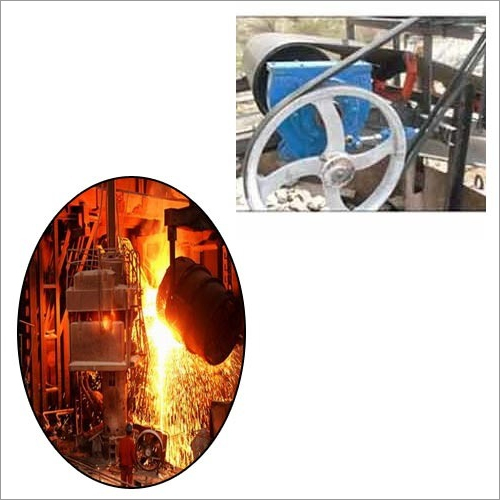

Steel Plant Conveyor Gear Box |

Road Construction Conveyors Gearbox |

|

Power Plant Conveyors Reduction Gearbox |

Gining Plant Conveyors Gearbox |

Stone Crusher Gearbox |

|

Cement Plant Conveyors Gear Box |

||

|

Helical SMSR Gear Boxes |

||

|

Helical SMSR Gear Box for Steel Industry |

Helical Gearbox |

Helical Gear Box |

|

Gearbox for Road Construction Machinery |

||

|

Road Construction Machinery Gearbox |

Road Construction Gear Box |

Drum Mix Plant Gearbox |

|

Gearbox for Road Construction Machinery |

Shaft Mounted Speed Reducers Gearebox for Road Construction |

SMSR Gear Box for Road Construction Industry |

|

Gearbox for Plants |

||

|

Industrial Gear Boxes for Power Plants |

Chemical Plant Gearbox |

Cement Plant Gearbox |

|

Salt Plant Gearbox |

SMSR Gearbox for Coal Industry |

Asphalt Plant Gearbox |

|

Sugar Plant Gearbox |

|

|

|

Industrial Gear Boxes |

||

|

Industrial Gear Boxes |

Non Reversible Gearbox |

Crusher Plant Hold Back SMSR Gearbox |

|

Reduction Gear |

Hot Mix Gearbox |

Pharmaceutical Machine Gearbox |

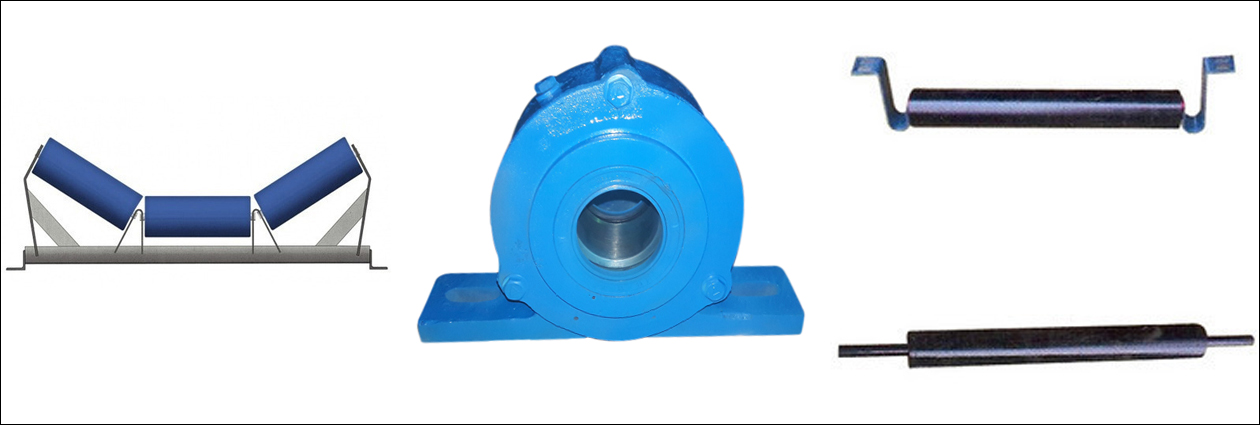

- Horizontal Gear Boxes

- Plummer Block

- Cast Iron Pulleys for Gearbox

- Cast Iron Pulleys

- Sun Gear Box

Infrastructural Set-Up

We have divided our infrastructure into different sections as per the requirements of the job. Latest techniques and technology is used to ensure our operations are carried out in a seamless manner. We have set up an R&D division in addition to others, which is dedicated to intensive research work and introducing improved designs and new material for making our products lighter in weight and sturdy.

Some of the machines installed at our facility are:

- Casting machines

- Load testing machines

- Welding machine

- Material handling machines

- Sophisticated measurement tools

Our Quality

We have a separate division dedicated to quality assurance. We understand the dynamics of both national and overseas market and have made quality, topmost priority in our operations. This helps us in distinguishing ourselves from our competitors in the international market. We have aligned our quality assurance process with manufacturing and this is frequently reviewed to maintain its efficiency. Besides, we regularly train our employees on quality management.

The parameters on the basis of which our products are assessed are:

- Heat resistance

- Design integrity

- Wear and tear resistance

- Size and dimension